When a critical piece of equipment shows an unusual error code at 2 AM, the last thing a maintenance technician needs is to scroll through a 300-page manual looking for the troubleshooting procedure. When a quality engineer investigates a deviation, cross-referencing multiple Standard Operating Procedures (SOP) and work instructions shouldn’t take longer than the investigation itself.

Manufacturing relies not just on data, but on documentation as well. Equipment manuals, maintenance procedures, quality protocols, work instructions, training materials, change orders. This documentation is essential, but its sheer volume creates a practical problem: the information you need is there, but finding it quickly enough to matter is the challenge.

With Critical Manufacturing MES v11.2, we’re introducing two AI-powered capabilities designed specifically to address this reality: Ask AI and View Summary. These capabilities exist because there is a real problem to solve. Manufacturing teams need rapid access to information within dense technical documentation. AI happens to be the right tool for this job.

Documentation in Manufacturing

Equipment maintenance manuals can span hundreds of pages with detailed technical specifications, troubleshooting matrices, calibration procedures, and parts diagrams. Quality procedures reference other procedures. Work instructions evolve through revisions and changes. Training documentation accumulates as processes mature.

The knowledge is documented. The challenge is retrieval.

Traditional search mechanisms have tried to ameliorate the proliferation and scattering of information. Nevertheless, they are fundamentally bound to the user knowing the exact term they are looking for, but manufacturing problems don’t always present themselves with searchable keywords. An equipment error might require understanding the relationship between several subsystems. A quality issue might need context from multiple procedures. These situations require understanding context and meaning, not just keyword matching. They also, like a doctor making a diagnosis, have a decision tree of most likely issues and solutions, that require a context and an iteration process.

Two Capabilities, One Goal: Faster Access to Better Answers

Ask AI: Your Documentation Intelligence Layer

Ask AI allows users to interact directly with a large language model that has access to documents and attachments within Critical Manufacturing MES. Rather than searching for keywords, users ask questions and interact with documentation in natural language. The same way they would ask a colleague who knew the documentation thoroughly.

How it works in practice:

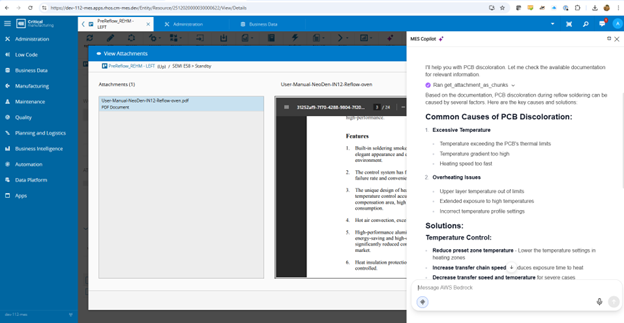

A maintenance technician encounters a recurring quality issue with a reflow oven. Instead of manually searching through the equipment manual, they open Ask AI and type: “What causes PCB discoloration?”

The AI analyzes the relevant maintenance documentation and provides a focused answer drawn from the manual, including the likely causes, the step-by-step troubleshooting procedure, and any safety precautions specific to that error condition.

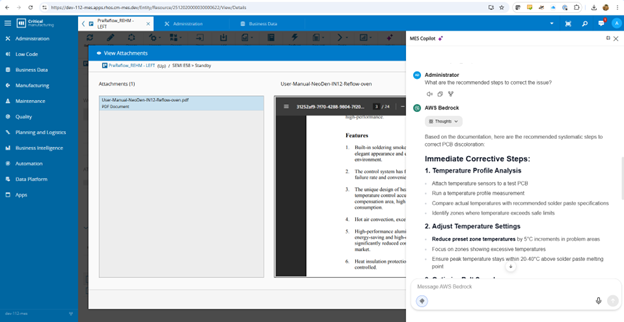

The technician can follow up: “What are the recommended steps to correct the issue?”

The expertise and decision making remains with the technician. What changes is how quickly they can access the documented procedures that inform their decisions.

View Summary: Rapid Document Comprehension

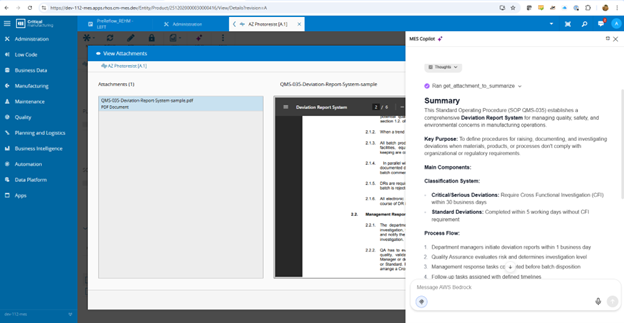

View Summary generates concise summaries of selected documents or attachments, with the ability to ask follow-up questions about specific aspects of the content.

Typical use case:

A quality engineer receives a 45-page deviation report that requires review and response. Rather than reading the entire document linearly to understand its scope, they generate a summary that provides:

- The core issue being addressed

- Key findings and root causes identified

- Recommended corrective actions

- Affected products or processes

With this context established in minutes rather than hours, the engineer can then ask targeted questions: “What validation testing was performed?” or “Which suppliers are mentioned in this report?”

The summary provides situational awareness. The follow-up questions allow focused deep-dives into areas that matter for the engineer’s specific responsibility.

Why These Capabilities, Why Now

We evaluate every potential AI integration against clear criteria:

Does it solve a real, recurring problem? Documentation access and comprehension are consistent pain points across manufacturing operations. Time spent searching is time not spent solving problems.

Does it integrate naturally into existing workflows? These capabilities live within the MES interface, accessible where users already work with documents and attachments. There’s no separate system to learn, no context switching required.

Does it enhance rather than replace human expertise? The AI provides information and context. The maintenance technician still diagnoses the equipment. The quality engineer still makes the compliance judgment. The production supervisor still decides on the corrective action. We’re accelerating access to documented knowledge, not attempting to automate technical decision-making.

Is it built on a foundation we can extend? These capabilities use AWS Bedrock, providing enterprise-grade security and a platform we can build on as AI technology matures and as we identify additional high-value applications in manufacturing operations.

This release represents one deliberate step in a longer strategic direction: progressively augmenting Critical Manufacturing MES with intelligence capabilities that align with how manufacturing actually works.

Technical Foundation: Built for Manufacturing Environments

The implementation uses AWS Bedrock, which means:

- Enterprise-grade security and compliance standards apply

- Flexibility in model selection as AI capabilities evolve

The AI works with documents and attachments already managed within Critical Manufacturing MES: maintenance manuals, work instructions, SOPs, quality procedures, change orders, training materials. If it’s documented in your MES, Ask AI can help users find relevant information within it.

Using AI Responsibly in Manufacturing

We are clear-eyed about what AI does well and what it does not. Large language models excel at understanding natural language, identifying relevant information across large documents, and synthesizing that information into coherent answers. They’re powerful tools for information retrieval and comprehension.

They are not infallible. AI-generated responses should be verified against source documentation for critical decisions, just as you would verify information from any source. The AI cites its sources, allowing users to validate responses against the original documentation. This is crucial, the user is able to traverse, validate and deepen his understanding by leveraging all the original references the AI provides.

This is AI as an assistant, knowledgeable, fast, helpful, but not as a replacement for human judgment in manufacturing operations.

Getting Started

These capabilities are available now in Critical Manufacturing MES v11.2. There’s no complex setup required. If you are managing documents and attachments in the MES, you can start using Ask AI and View Summary immediately.

This is an evolving capability, and your real-world experience will help shape how we extend it.

Looking Ahead

We don’t add technology because it’s trending. We add capabilities that deliver measurable operational value, fewer errors, faster decisions, better outcomes on the shop floor. All of this leveraging a robust shop floor control system, that has years of context and experience, providing a standard and guarded way for AIs to operate.

Document intelligence solves a specific, recurring problem: rapid access to critical information buried in complex technical documentation. It’s a natural fit for AI, and it delivers tangible results. But it’s one capability among many we’re developing.

Our broader vision is clear: we are transforming Critical Manufacturing MES from a transaction system into an intelligent partner. Not by bolting on chat bots or AI assistants, but by using AI to build the actual features and solutions manufacturing operations need.

This means:

Frontline empowerment - AI that augments operators, technicians, and supervisors with the right information and insights when they need them, helping people work smarter.

Operational intelligence - AI that provides clarity and foresight across processes, equipment, and materials, identifying issues before they become problems.

Accelerated value - AI that shortens implementation timelines and reduces complexity, getting you to measurable business results faster.

The document capabilities in v11.2 are another keystone in our foundation. We are building deliberately, learning from real-world usage, and advancing where it genuinely matters.

The MES should progressively understand more about your operations and provide increasingly sophisticated support to the people running them. Not to replace their expertise, but to amplify it.

That’s the direction we’re committed to. V11.2 is the first step.

Author

Hi! My name is Ricardo Magalhães. 🤘

You can check me on LinkedIn