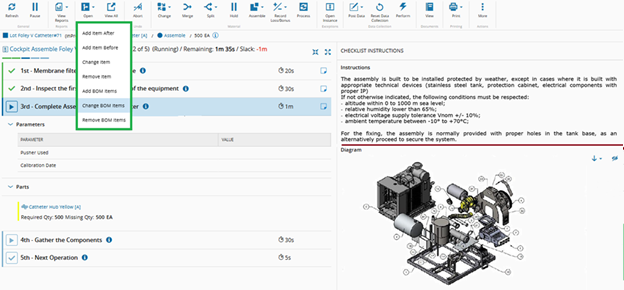

In the industrial equipment industry, it’s not uncommon for operators, during the assembly of parts (guided by a Checklist), to have to make unforeseen changes, such as modifying certain Items of the Checklist or even replacing a component or adjusting the quantity to be used.

BOM - Checklist & Material Deviations Overview

- Add/Change/Remove Checklist Items

- Add/Change/Remove BOM Items

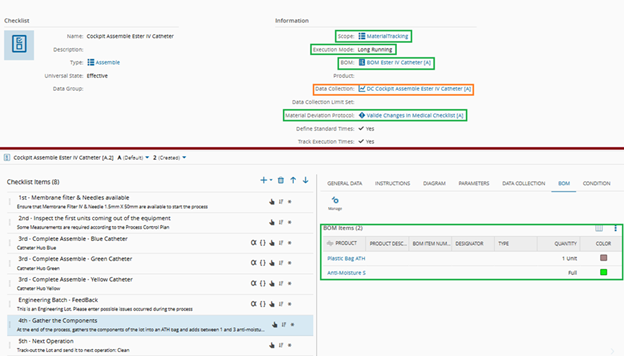

However, these change requests are not immediately implemented. They need first to be reviewed and either approved or rejected through a Material Deviation protocol. Therefore, this protocol must be also assigned to the Checklist to enable this functionality.

Configuration Highlights

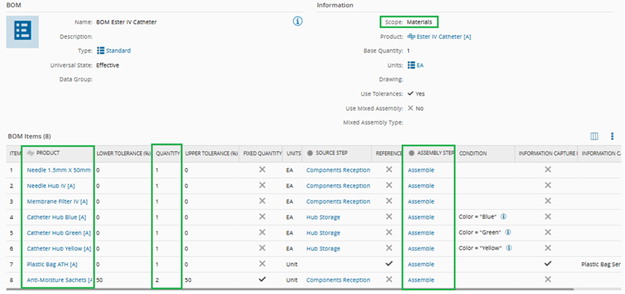

- Bill of Material configuration

Create (or import into MES) the Bill of Material. This entity offers various options, but the most important properties for this use case are the BOM scope, the products with their respective consumption quantities, and the assembly process step."

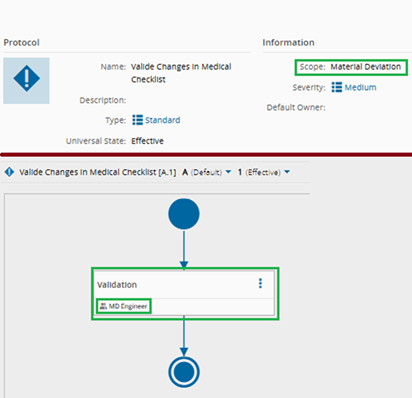

- Protocol Setup

A protocol of Scope “Material Deviation” must be created to Review and then either approve or reject the changes requested. Its flow chart can be minimal, with a single approval state, or more elaborate with multiple states and approval levels.

Data Collection and Data Collection Limit Set Optionally, create a Data Collection and a Data Collection Limit Set to capture process data during assembly process

Checklist Configuration

- Context Tables

For the Assembly Step, fill the context tables for BOM, Data Collection and Checklist

Demo

Benefits

Enhanced Flexibility During Assembly: Operators can request changes “on the fly” without completely stopping production, adapting to unforeseen adjustments smoothly.

Controlled Change Management: All requested deviations are reviewed and either approved or rejected via the Material Deviation protocol, ensuring changes are tracked and authorized before implementation.

Single GUI for all operations: With the integration of BOMs, protocols, Checklists, and optional data collection, documents and technical drawing, MES users can perform all tasks without switching between different features

Final Thoughts

Author

I’ve been with Critical Manufacturing since 2018, starting out as an MES Consultant. Earlier this year, I stepped into the recently created Advocate & Architecture team. My role sits at the intersection of technology, communication, and strategy. Making sure solutions are technically sound and that everyone understands how to use or build them.

You can check me on LinkedIn