Introduction

In high-precision manufacturing environments, such as semiconductor fabs, maintaining the cleanliness and integrity of production containers (like FOUPs, cassettes, among other carriers) is essential to prevent particle contamination and yield loss.

From my own experience, as a former Production Engineer who was responsible for managing all sort of handling materials, I’ve seen firsthand how inadequate container maintenance can lead to a range of production issues, including:

- Equipment events, such as end-effector failures during wafer pick-up or placement caused by damaged slots or faulty container docking.

- Handling events, when worn or defective handles result in containers being dropped on the shop floor.

- Material events, where the container itself damages or contaminates the material it is meant to protect.

Hence, maintaining FOUPs and similar containers in top condition is directly tied to product yield and contamination control. As highlighted in an Entegris article (linked at the end of this post) on yield advantages through maintaining and upgrading FOUP populations, proper FOUP maintenance and lifecycle management are critical factors in sustaining high yield and equipment reliability.

What is Container Maintencance LifeCyle Management?

Container Maintenance Lifecycle Management refers to the continuous process of tracking, maintaining, and managing the condition of containers throughout their entire operational life.

In this context, the MES (Manufacturing Execution System) plays a pivotal role by monitoring the container’s journey from the moment it is first introduced into the production line until it is eventually retired or scrapped.

Throughout its lifecycle, the MES:

- Tracks usage history, recording how many times the container has been docked, undocked, or used for material transfers.

- Monitors key operational events, such as equipment interactions, maintenance completions, or incidents.

- Applies preventive maintenance rules, automatically determining when maintenance should be performed based on actual usage or time thresholds.

- Ensures traceability, maintaining a complete digital record of each container’s performance and interventions.

This closed-loop approach ensures that every container is kept in optimal condition, supporting consistent process quality, equipment reliability, and yield protection.

How is container usage tracked in MES?

Critical Manufacturing MES capture all relevant line events that might affect container condition over time. Each time a container passes by a load port, it’s used in a given transferring process or is engaged in specific process operations, the MES automatically increments its usage count. Once a predefined threshold is reached, the system can trigger a maintenance action, ensuring the container is cleaned, inspected, or replaced at the optimal time. Below, a detailed list of events that CM MES is tracking:

- Add Container to Container

- Add Material to Container

- Dock Container

- Empty Container

- Manage Container Positions

- Remove Container from Container

- Remove Material from Container

- Ship Material

- Track-in Material

- Transfer Container between Containers

- Transfer Material between Containers

Some of the above events will be tracked at equipment level (or Resource, in MES terms), but not every Resource will be accountable to increment container usage. Critical Manufacturing MES has the flexibility to allow user to wether define if that Resource will count the container usage or not. This process can be easily handled by simply toggling a Resource property: Enable Container Maintenance Events.

Below, an illustration of this property enabled:

How to setup and perform usage-based Preventive Maintenance Plan?

The process begins with the creation of a Maintenance Plan. As shown in the image below, the user starts by configuring the generic properties of the object. The flexibility that Critical Manufacturing MES provides allows the user to define which schedule type to adopt.

For our use case, since we want to track the number of times a given container has been used, the Usage-Based option should be selected. However, CM MES also allows maintenance plans to follow a Time-Based schedule — enabling users to track containers according to specific time periods, or even to combine both scheduling types (Usage-Based and Time-Based) to run in parallel.

Note: There are cases where customers will also track containers based on time.This is often necessary because containers may be stored for long periods, during which their condition should still be periodically evaluated.

The next step is to define how the scheduling will work.For an Usage-Based Maintenance Plan, the user needs to configure the details of the counter. In the example below, the user wants to track how many times a given container has been docked. An interval is defined for the number of times a container is allowed to dock before a maintenance activity is expected to occur.

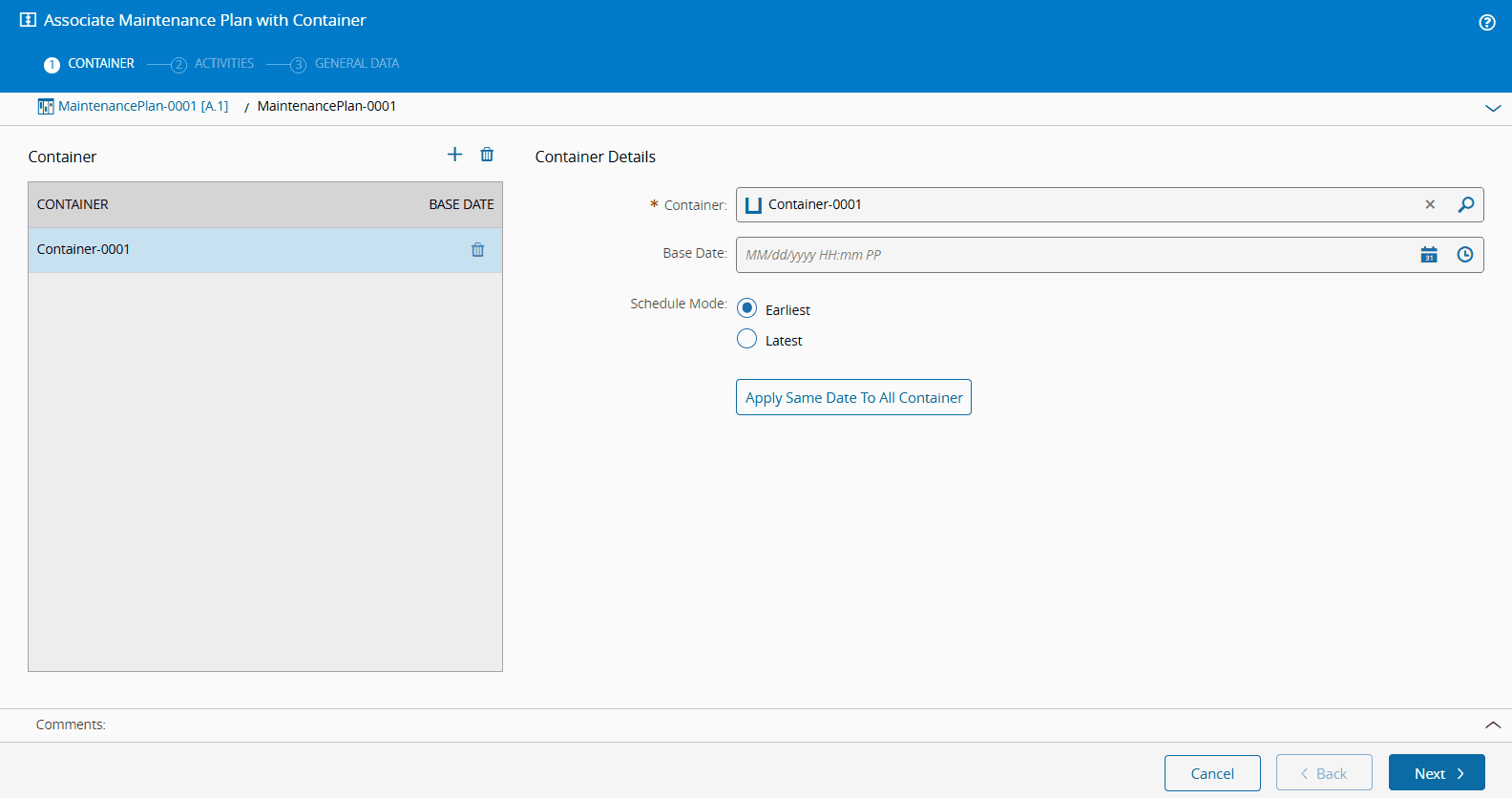

Once the Maintenance Plan is created, the next step is to associate it with a container, which will be the object of usage tracking. The illustration below shows how the user can easily select an existing container in the system and associate it with the Maintenance Plan previously created.

Demonstration

In the following video, an operational scenario is demonstrated where two maintenance activity instances run in parallel. In one activity, the system tracks how many times a given container is docked into LoadPorts; in the other, it tracks how many times the same container is undocked from LoadPorts.

Why it matters?

Usage-based preventive maintenance goes beyond traditional time-based scheduling by ensuring that maintenance aligns with actual utilization.

As key benefits we find:

Higher yield protection: Reduces contamination risk by maintaining container cleanliness and sealing performance.

Improved equipment reliability: Containers are serviced at the right time, avoiding mechanical wear issues.

Optimized operations: Avoids both premature maintenance and unplanned downtime.

Full traceability: The MES logs every use, threshold, and maintenance action for complete historical insight.

Sustainability and cost efficiency: Maintenance resources are allocated based on real need, reducing waste and downtime.

Ultimately, this feature enhances both production efficiency and product integrity, aligning with the industry’s drive toward smarter, data-driven manufacturing.

Final Thoughts

As fabs continue to increase automation and production density, maintaining container integrity becomes even more critical to protect yield.

By connecting usage data, maintenance planning, and container tracking directly within the MES, manufacturers can close the loop between operations and reliability — ensuring each FOUP or carrier remains in optimal condition throughout its lifecycle.

Links and References

Author

Hello, my name is Pedro Teixeira

I’ve been working at Critical Manufacturing for several years. As both a MES Consultant and Product Owner, my main role is to help deploy our system and tailor it to customer needs. I also support our Documentation team with tutorials, and recently, I’ve started writing blog posts to share insights around CM MES features.

You can visit me at  LinkedIn

LinkedIn