In manufacturing, transitions matter. Whether switching between products, services, or batches, the way we prepare our resources can make or break quality.

With version 11.2, Critical Manufacturing MES brings a more intelligent and flexible approach to Setup and Line Clearance, helping teams ensure that every material starts its journey on a clean, verified line.

This feature supports both always-on setup and changeover-triggered setup, giving manufacturers the tools to model real-world production logic with precision.

What Is Setup and Line Clearance?

Setup and Line Clearance is a feature which ensures that resources — equipment, workspaces, and tools — are properly prepared before processing begins. It helps prevent contamination, mix-ups, and leftover documentation from previous jobs.

Setup can be triggered:

- Always: Every time a material is tracked in.

- On Changeover: Only when a key characteristic (for example, Product, Product Group, Service) changes.

Configuration Highlights

There are several parts that play a role in the configuration of this feature, let’s break down how this works in practice.

🔧 Resource Configuration

Each resource can be configured with:

Setup Mode: Choose between Always or On Changeover.Use Different Setup Operations: Enable if different checklists (and/or Documents and/or Data Collections) are needed for changeover vs. regular setup.

Example:

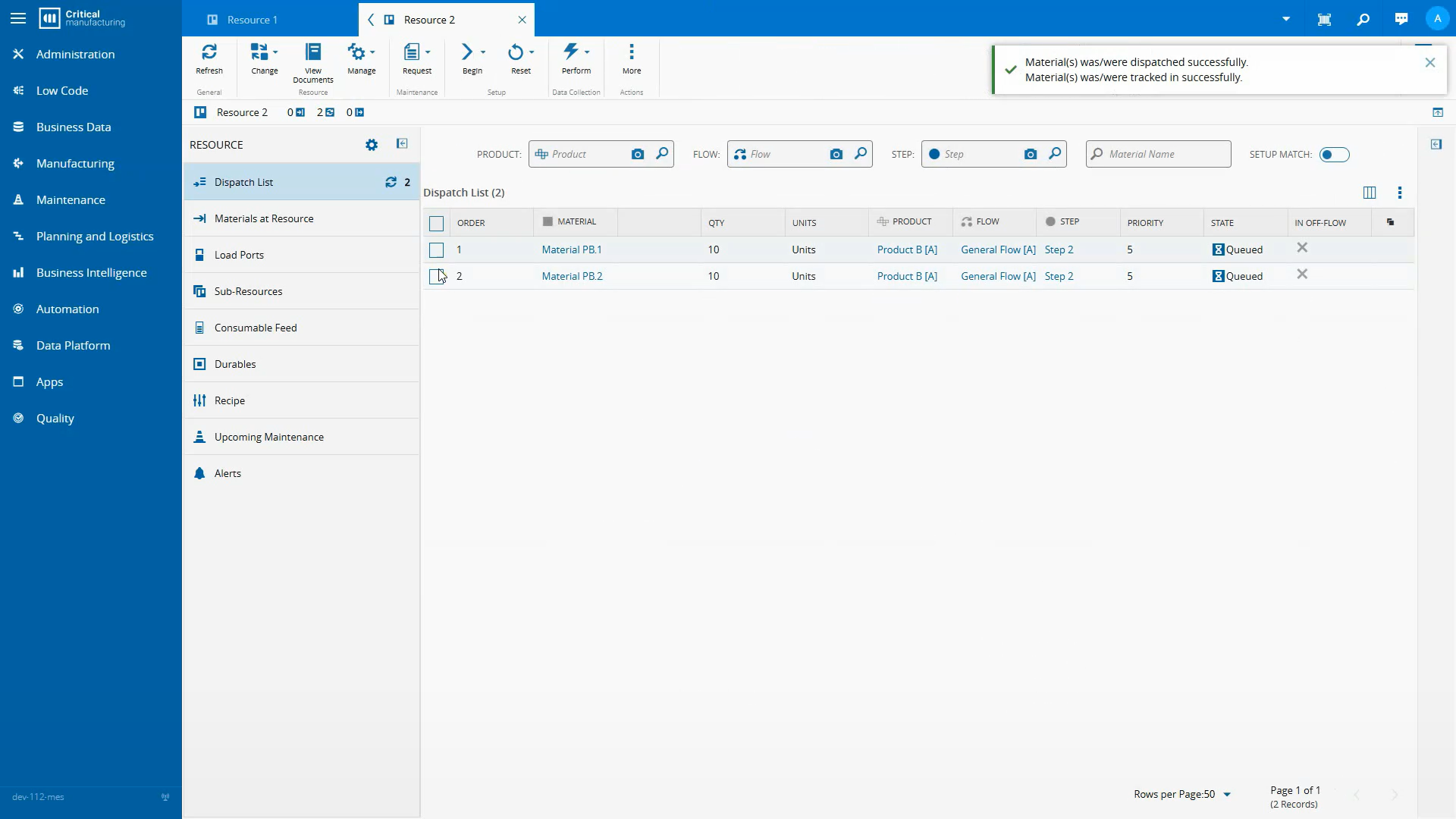

- Resource 1: Setup only when the service changes.

- Resource 2: Setup always required, with different checklists depending on product group.

⚙️ Step Configuration

Steps define which characteristic should be evaluated for changeover:

- Step 1: Setup triggered by Service change.

- Step 2: Setup triggered by Product Group change.

This allows fine-grained control over when and why setup is required, and ensures that the correct checklist is used.

📝 Checklist, Data Collection and Documents

Setup operations are supported by:

- Checklists: Executed during setup, tailored to the context.

- Data Collections: Capture key parameters during setup.

- Documents: Displaying relevant information to the user.

And these configurations address scenarios where a step may require one checklist for same product group, and a different one for changeover.

Pre-Setup Option

There is also a new option to prepare a resource before the material arrives, by using the Perform Pre-Setup operation to get ahead of the curve. This operation allows setup to be completed in advance, improving readiness and reducing delays.

Benefits

Features like Setup and Line Clearance in version 11.2 bring meaningful benefits across all levels of users in Critical Manufacturing MES, supporting operators, supervisors, and engineers alike with smarter, more structured transitions:

- Improved Quality: Prevents cross-contamination and misprocessing.

- Operational Efficiency: Setup logic is automated and context-aware.

- Traceability: Setup actions are recorded and auditable.

- Flexibility: Supports both reactive and proactive setup strategies.

Final Thoughts

Setup and Line Clearance in 11.2 reflects our ongoing commitment to modeling real-world manufacturing complexity. It’s not about fixing what was broken — it’s about evolving toward smarter, cleaner, and more reliable production.

For configuration steps and examples, check out the Setup and Line Clearance Tutorial.

Author

Hi! My name is Sofia Rodrigues. ☺️

I joined the Critical Manufacturing family back in the striking year of 2020 as an MES Consultant/Functional Analyst. In 2023, I transitioned to the Product Documentation team, where I now focus on designing and creating content.

You can check me on LinkedIn

Skills: Functional Analysis | System Testing | User Training | Technical Writer