In manufacturing, quality doesn’t just happen at the beginning or end of a process — it must be maintained throughout. That’s where Line Verification comes in.

With version 11.2, Critical Manufacturing MES introduces a new way to ensure that materials in production are verified at the right moments, especially during sensitive transitions like shift changes or mid-shift breaks. This feature brings in-process control into sharper focus, helping teams maintain consistency, traceability, and compliance—without disrupting the flow.

What Is Line Verification?

Line Verification is an event-driven feature that enables in-process checks while a material is being processed. It’s particularly useful in high-sensitivity environments where conditions like temperature, humidity, or operator handovers can impact product quality.

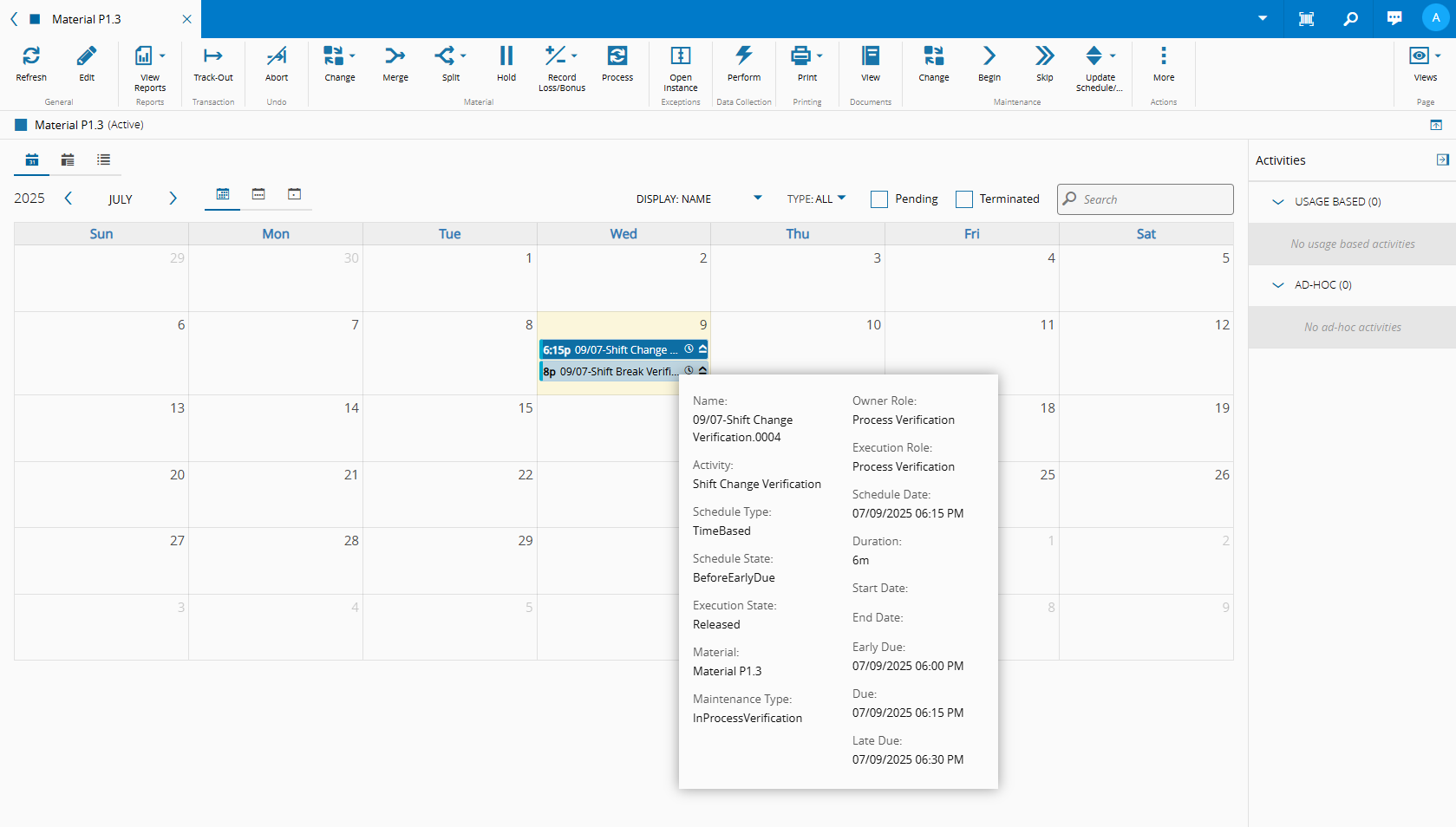

Once a material is tracked in, MES dynamically assigns a Maintenance Plan Instance that stays active until the material is tracked out. During this window, verification activities can be triggered based on time or shift events.

Configuration Highlights

Let’s walk through the key elements that bring this feature to life.

🏭 Calendar and Shift Definition

To support time-based triggers, a calendar must be configured with a Shift Definition that reflects your operational schedule. For example, a 24-hour operation might use six 4-hour shifts.

This setup allows MES to calculate when shift breaks or changes occur, which is critical for triggering verifications at the right time.

⚙️ Step Configuration

To enable Line Verification at a specific step, set the Enable In-Process Verification property to True. This tells MES to monitor materials at that step and apply the appropriate verification logic.

📝 Checklist and Data Collection

Verification activities are defined using, for example checklists or data collection, and can be assigned for different events.

📋 Maintenance Plan

The core of Line Verification is a Maintenance Plan of scope In-Process Verification. It defines:

- Trigger: When the activity should occur (e.g., on shift change).

- Duration: How long the activity takes.

- Due Window: How soon it must be completed.

- Tolerance: Flexibility around the due time.

These plans are linked to steps using the Material In Process Verification Context Smart Table, which resolves the correct plan based on context.

If a material is still in-process when a verification is due, MES will block track-out until the activity is completed—ensuring nothing slips through the cracks.

Benefits

Line Verification in 11.2 brings meaningful improvements to how in-process quality is managed:

- Proactive Control: Verifications are triggered by real-world events, not just process steps.

- Improved Traceability: All actions are logged and linked to the material.

- Operational Clarity: Operators know exactly what to do and when.

- Compliance Support: Helps meet regulatory and quality standards.

Final Thoughts

Line Verification reflects our ongoing effort to bring MES logic closer to the realities of the shop floor. It’s not just about tracking what happens — it’s about ensuring the right things happen, at the right time, with the right accountability.

For configuration steps and examples, check out the Line Verification Tutorial.

Author

Hi! My name is Sofia Rodrigues. ☺️

I joined the Critical Manufacturing family back in the striking year of 2020 as an MES Consultant/Functional Analyst. In 2023, I transitioned to the Product Documentation team, where I now focus on designing and creating content.

You can check me on LinkedIn

Skills: Functional Analysis | System Testing | User Training | Technical Writer