Manufacturing is about more than just assembling products — it’s about managing materials efficiently, including what’s left over.

With version 11.2, Critical Manufacturing MES brings powerful support for negative BOM item quantities, enabling real tracking of by-products generated alongside main products.

This innovation answers real user requests and opens the door to smarter, ecologically aware production management. Let’s explore what this feature means, the problems it solves, and how it helps turn production “waste” into value.

The Challenge: Tracking By-Products in Manufacturing

In many manufacturing processes, producing a final product also creates by-products or leftovers that must be accounted for. Simple examples include:

- Juice production generating fruit peels usable for essential oils or bio-fuels.

- Metalworking creating scrap material that can be recycled.

- Food processing yielding waste products possible as feed or compost.

It is common for systems to be focused only on components consumed during assembly, making it difficult to record by-products as part of the production flow.

This gap caused:

- Lack of traceability for valuable leftovers or secondary materials.

- Difficulty integrating by-products in inventory and reporting.

- Missed opportunities to repurpose or recycle materials efficiently.

What’s New in 11.2: Negative BOM Item Quantities

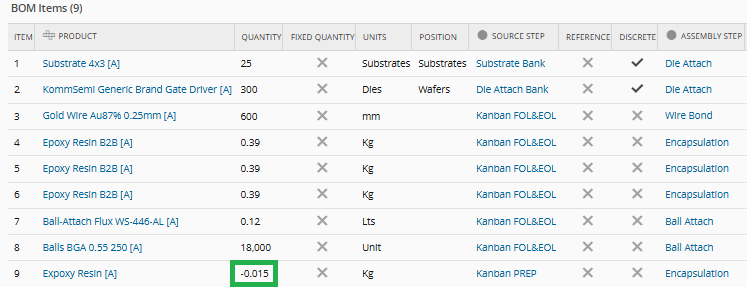

Critical Manufacturing 11.2 introduces native support for negative quantity BOM items, allowing by-products to be defined and tracked directly within the BOM. Here’s what that entails:

By-products are BOM items with negative quantities, configurable only under Materials scope.

Negative Quantity BOM Items Consumption happens in reverse: Instead of reducing inventory, assembly increases the quantity of by-products.

Substitutes are not allowed for negative items, ensuring clear material tracking.

Practical Benefits

- Integrates by-product tracking seamlessly into BOM-driven assembly/disassembly.

- Provides full visibility and traceability of all materials flowing through production.

- Simplifies setup by avoiding the need for separate “waste” processes or manual inventory adjustments.

- Enhances data quality for cost control, reporting, and sustainability initiatives.

Final Thoughts

Handling by-products efficiently is vital for modern manufacturing - both for operational accuracy and environmental stewardship. Critical Manufacturing MES 11.2’s negative quantity BOM items empower companies to track, manage, and repurpose leftovers.

By embracing this feature, manufacturers align with sustainability goals while gaining operational clarity. It’s another step toward smarter, greener production that benefits the business and the planet. 🌱

For more details and configuration tips, explore our full BOM Tutorial series and User Guide.

Author

Hi! My name is Sofia Rodrigues. ☺️

I joined the Critical Manufacturing family back in the striking year of 2020 as an MES Consultant/Functional Analyst. In 2023, I transitioned to the Product Documentation team, where I now focus on designing and creating content.

You can check me on LinkedIn

Skills: Functional Analysis | System Testing | User Training | Technical Writer