Manufacturing rarely fits neatly into “one method fits all.” Some processes require the best of both worlds — manual precision assembly alongside automated, event-driven consumption.

How do you achieve that without compromising traceability, efficiency, or shop floor clarity?

Critical Manufacturing MES 11.2 introduces this capability with Mixed Assembly. This feature allows multiple BOM assembly types to coexist seamlessly within the same production step.

Let’s dive into what Mixed Assembly means, the challenges it solves, and how it unlocks new operational flexibility.

The Challenge: Diverse Assembly Needs in One Step

Typical BOM consumption behavior in MES systems has historically been fixed at a contextual level, all items in a BOM consumed the same way per step. But manufacturing reality is - if you allow me - messier:

- Some components need manual tracking and explicit assembly to ensure quality or customization.

- Others suit an automated assembly triggered at material track-in or track-out events for speed and reliability.

- Attempts to blend these had complex workarounds: splitting steps, reconfiguring BOM contexts, customizations, or compromising traceability.

Introducing Mixed Assembly: The Best of Both Worlds

In version 11.2, the Mixed Assembly feature shifts control from BOM context to the BOM Item level, enabling different assembly type side-by-side within the same production step.

How it Works

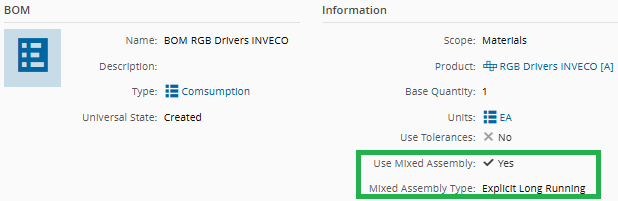

At the BOM level, enable the “Assembled Mix Mode” and define a base explicit assembly type: Explicit, Explicit Add, or Explicit Long Running, and this behavior is fixed per BOM and cannot vary per context.

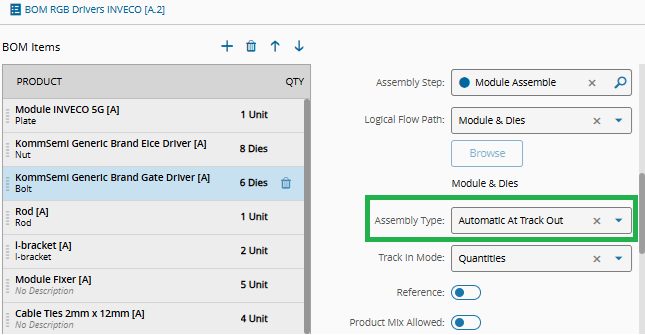

BOM Mixed Assembly At the BOM item level, override the manual behavior for selected components by specifying automatic consumption behaviors: Automatic at Track-In or Automatic at Track-Out.

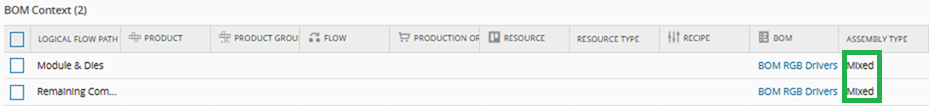

Automatic at Track-Out In the BOMContext Smart Table, set the Assembly Type to

Mixed.

BOMContext Smart Table Available only for BOM Scope is set to

Material.Components flagged for automatic assembly consume themselves during standard material events, while others require manual operator assembly.

Real-World Benefits

⚡ Enhanced Flexibility

Manufacturers can now:

- Mix delicate, manually assembled parts with automated consumables on a single line.

- Avoid splitting production steps unnecessarily, simplifying flow and operator training.

🚀 Optimized Efficiency

- Automated consumables (like adhesives or fasteners) reduce manual errors and speed up throughput.

- Manual assembly items maintain the needed control for quality and customization.

🔖 Improved Traceability

- All assembly actions remain fully recorded and traceable, regardless of consumption mode.

- BOM item-level assembly types offer granular insights into exactly how components were consumed.

Example Use Case

Imagine a production step where:

- Product A requires manual assembly of a customer-specific BOM Item Module, to be assembled with Explicit assembly type.

- Meanwhile, BOM Items like screws and labels are automatically assembled at Track-Out.

The BOM would have to be configured to have the Assembled Mix Mode set to Explicit, and the BOM Item Module would inherit this assembly type. When configuring the BOM Items screws and labels, the Assembly Type needs to be Automatic at Track-out.

When configuring the BOM Context Smart Table, the system will automatically assume the Assembly Type as Mixed. The BOM should be configured with the Assembled Mix Mode set to Explicit, so that the BOM Item Module inherits this assembly type. For BOM items such as screws and labels, set their Assembly Type to Automatic at Track-out. When configuring the BOM Context Smart Table, the system will automatically recognize the Assembly Type as Mixed.

This way, Mixed Assembly enables this blend effortlessly, matching shop floor needs without complicated workarounds.

Final Thoughts

Mixed Assembly feature in Critical Manufacturing MES 11.2 is a game changer — joining flexibility, efficiency, and traceability on the factory floor. It addresses the diverse assembly needs within unified production steps, reflecting the true complexity of modern manufacturing.

Consult our detailed BOM Tutorial and User Guide to configure and roll out Mixed Assembly smoothly.

Author

Hi! My name is Sofia Rodrigues. ☺️

I joined the Critical Manufacturing family back in the striking year of 2020 as an MES Consultant/Functional Analyst. In 2023, I transitioned to the Product Documentation team, where I now focus on designing and creating content.

You can check me on LinkedIn

Skills: Functional Analysis | System Testing | User Training | Technical Writer