How do you make your BOM keep pace with real-world production?

In version 11.2, Critical Manufacturing MES raises the bar for BOM flexibility. Fixed consumption, tolerance ranges, information capture and assembly ad-hoc operations - these features solve longstanding challenges for every manufacturing engineer who has faced a process that refuses to fit a strict mold.

This post explores new capabilities, why it matters, and how it solves everyday problems on the shop floor.

Fixed Quantity BOM Items

What is the real challenge?

Most BOMs scale linearly: 10 products require 10 times the parts. But some processes break this rule. Think of disinfectants for sanitizing a line - whether you are assembling 1 or 1,000 units, only one bottle is used for the whole batch. The same is true for quality test kits or glue packs included per order, not per unit.

With 11.2, fixed quantity BOM Items enhancement, we enable direct configuration of BOM Items with a fixed quantity, regardless of batch size. Set it, and production reporting reflects reality.

This feature addresses concerns such as:

- Inaccurate material planning for fixed-use items

- Over-consumption and waste when “per unit” logic is reused by force

- Workflow rigidity for items needed just once per order

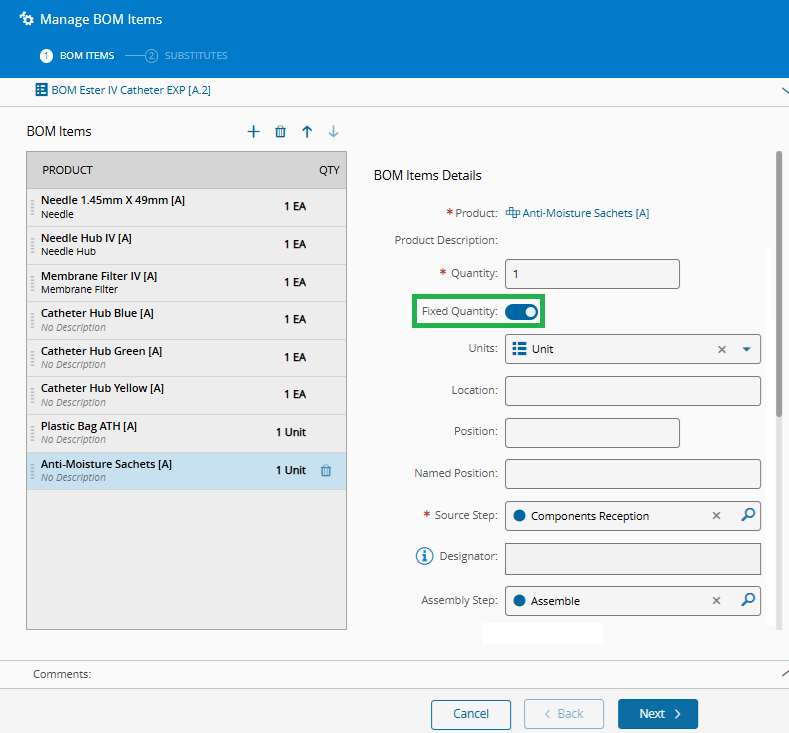

Setting up Fixed Quantity BOM Items

To use this feature, choose the option Fixed Quantity in the BOM Item.

Note: This is only applicable for BOMs of Scope Materials and when the Assembly Type is Automatic At TrackIn, Automatic At TrackOut or Explicit Long Running.

BOM Consumption Tolerances

Why does this come up?

Real life rarely matches CAD. For example, a BOM might call for 1.2m² of insulation foam, but the operator uses 1.5m² to ensure coverage, and cutting isn’t always perfect. There are numerous cases where the theoretical quantity and the actual consumed quantity are not the same.

New in 11.2 is the option to configure upper and lower tolerance limits for BOM Items. If operators use a little, it’s OK - the system registers the actual quantity, as long as it falls within the allowed range. Processes become smoother, and data reflects what really happened.

This feature ensures that the following needs are met:

- Frustrating failures or extra transactions when the consumed quantity doesn’t exactly match the theoretical value

- Operators forced to “cheat” the system or run extra steps to reconcile usage

Setting up BOM Consumption Tolerances

To use this feature, choose the option Use Tolerance at the BOM Level. Also, for each BOM Item, define the percentage values for Lower and Upper Tolerance (0% if no tolerances are applied).

Note: This is only applicable for BOMs of Scope Materials and when the Assembly Type is Manual.

Capture Information for BOM Items

Where is the pain point?

Some assembled products include externally sourced or ad-hoc items (like a cable tie, customer-supplied component, or anything with a serial number). These parts aren’t always MES materials, and perhaps the operator just needs to capture their details for traceability or compliance.

In version 11.2, you can mark the BOM Item with “Capture Information”, and the user can now enter key data (serial, batch, notes, etc.) at assembly time, associating it directly with that product and process.

Barriers removed with this feature:

- No easy way to tie serials or batch numbers to the operation

- Missing traceability for critical, non-inventoried items

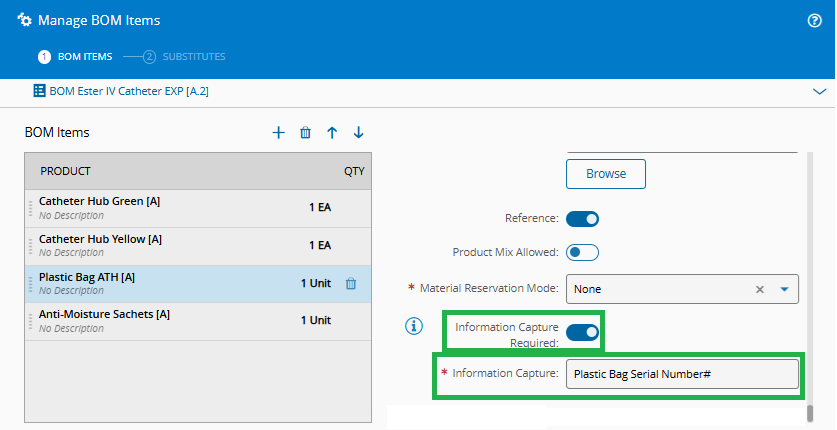

Setting up Capture Information for BOM Items

To use this feature, choose the option Information Capture Required in the BOM Item, then enter text freely for Information Capture Text.

Note: This is only applicable for BOMs of Scope Materials or Parts and when the Assembly Type is Manual.

Material Assembly History

What is the real-world challenge?

Repairs and rework are inevitable in manufacturing. Typically, processes require well-defined rework flows and steps, and MES systems are designed to handle these strict scenarios, such as replacing or removing faulty components. However, in some cases, removal or replacement must happen at any time and is not tied to a specific step in production. Addressing these situations often requires extra configuration, reduced flexibility, and sometimes even disorganization when reality didn’t align with the modeled process.

What is new on 11.2 is a new Assembly History Section for each material, where information is centralized and provides flexibility. Operators see the full record of what was assembled for Explicit Long Running assemblies, and can perform assembly related operations, independent of the step the material is at, namely:

- Add more of a component if needed

- Remove excess or faulty parts

- Replace specific pieces

This has the potential to decrease workflow bottlenecks. Corrections can be made when and where the issue is found, keeping production running and records accurate.

Roadblocks cleared with this feature:

- Painful setup - dedicated flows and BOMs just for repairs

- Delays if the “repair” step wasn’t planned where it’s needed

Setting up Material Assembly History

No initial setup is required to use this feature. However, it can only be used if the Assembly Type is long-running (manual) and only once the BOM instance is closed.

Final Thoughts

Manufacturing is rarely one-size-fits-all. These latest BOM enhancements put the power and nuance back in the hands of teams building real products, not just following idealized flows.

Want to learn more? Explore our BOM User Guide BOM User Guide and Tutorial.

Author

Hi! My name is Sofia Rodrigues. ☺️

I joined the Critical Manufacturing family back in the striking year of 2020 as an MES Consultant/Functional Analyst. In 2023, I transitioned to the Product Documentation team, where I now focus on designing and creating content.

You can check me on LinkedIn

Skills: Functional Analysis | System Testing | User Training | Technical Writer