Imagine building a turbine, an aircraft, or a large industrial machine. Several operators are working simultaneously: one installs front panels, another connects wiring, while someone else prepares subsystems. These tasks don’t follow a strict order – they happen in parallel.

Some MES systems struggle here. They expect a single “current Step” in a sequence. But in real-world assembly, parallel operations are the norm, not the exception.

That’s where the Process Activities feature comes in.

Overview

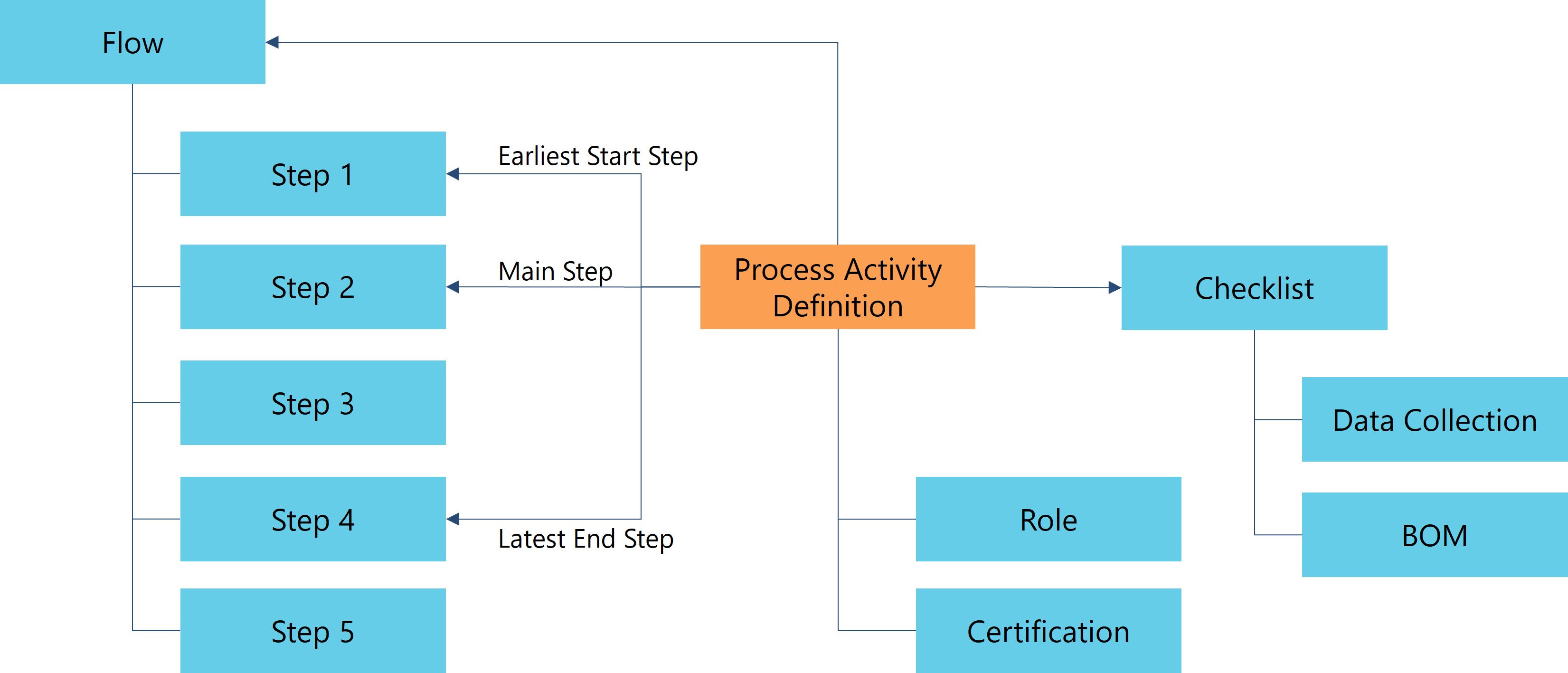

Process Activities let you define and track independent tasks that run in parallel on the same unit of production. Each activity has its own:

- Checklist and instructions

- Time tracking

- Role and Certification requirements

- Execution rules (for example, one operator at a time vs. multiple operators allowed)

Instead of forcing everything into a rigid sequence, Critical Manufacturing MES adapts to how work really happens.

How it works

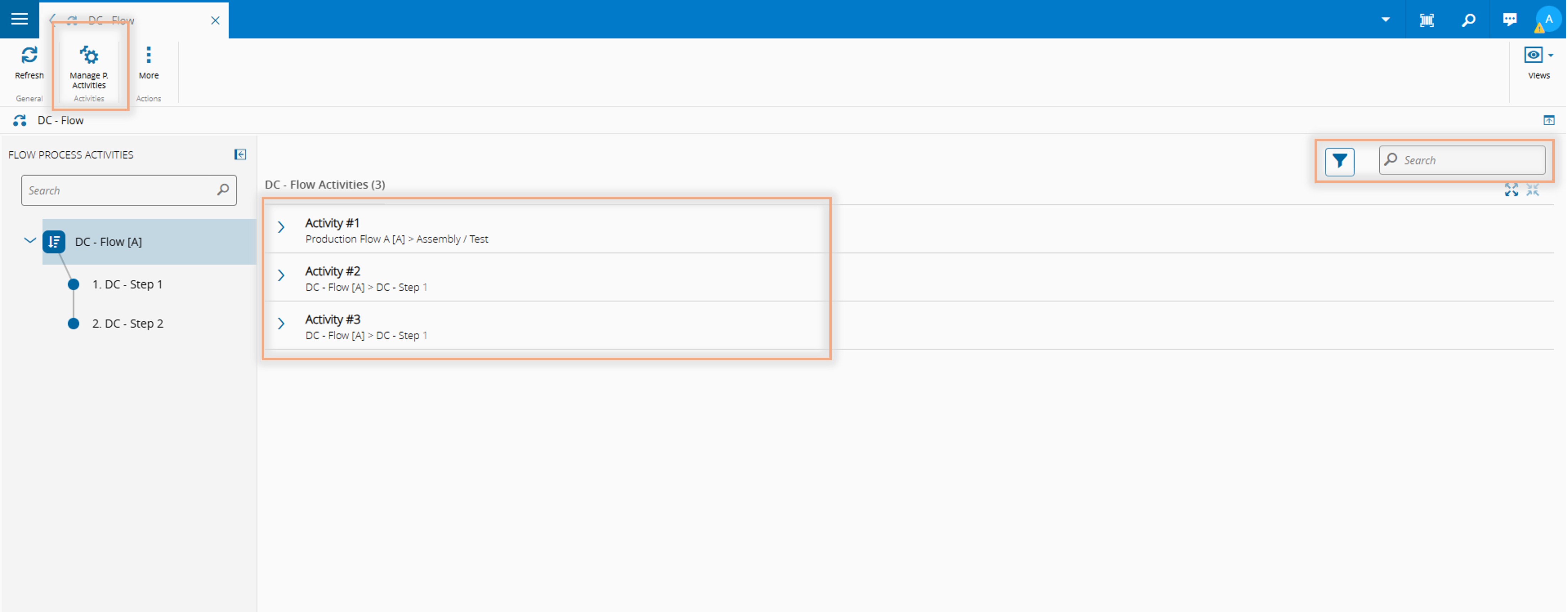

🔧 Setup – In the Flow, you define Process Activity Definitions (PADs). Each PAD represents an independent task that can span one or several Steps, with Checklists that can be executed independently across several Steps – but the key is flexibility:

- An activity can apply to a single Step or extend across multiple Steps.

- It can be restricted to one Employee or allow multiple Employees to collaborate in the same activity, in parallel.

- Several activities run at the same time (in parallel) for the same production unit.

- Rules such as required Roles or Certifications ensure only qualified Employees can perform the activities.

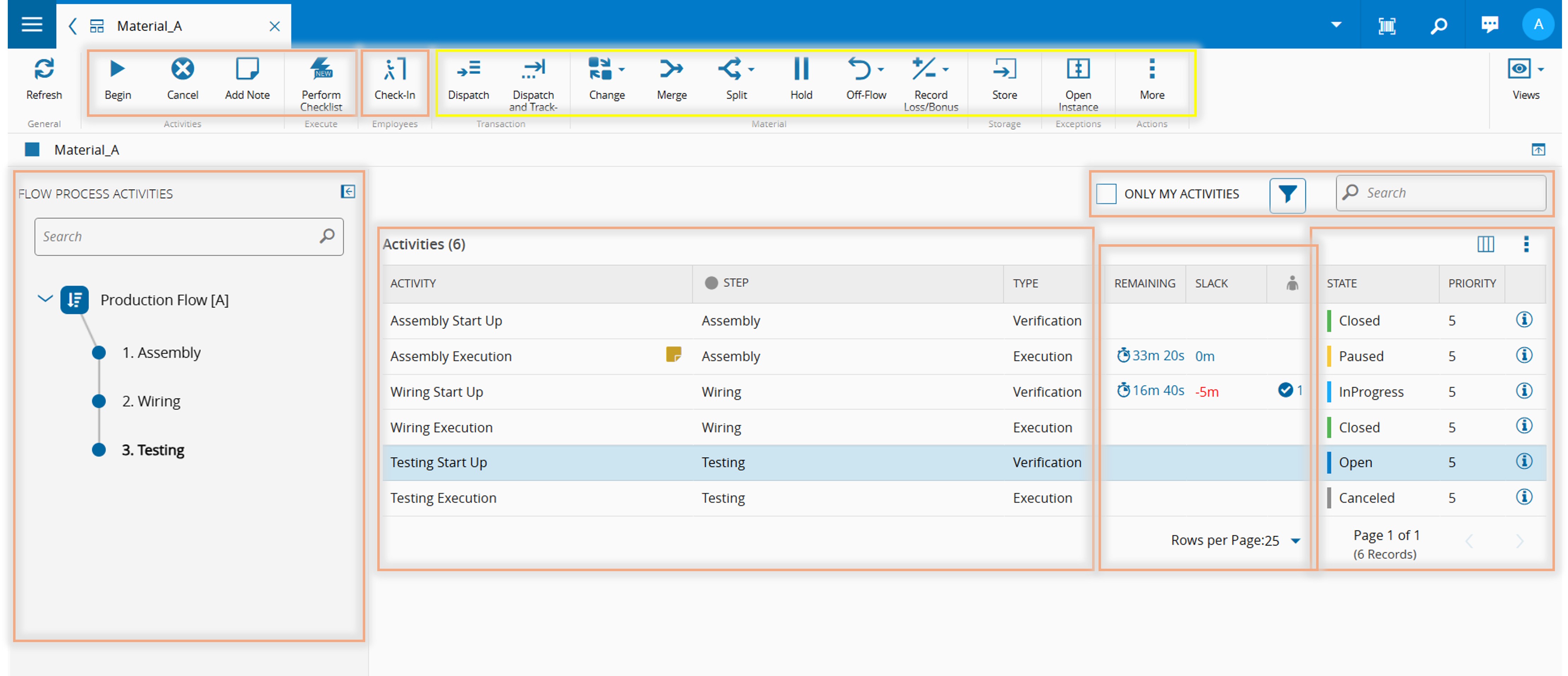

🚀 Execution – When a production unit reaches the defined Step, the system automatically generates the activity. Employees then:

- See the activity in the Process Activities View.

- Check in.

- Complete the Checklist independently, even while other activities run in parallel on the same unit.

- Close the activity once it is complete, while others may still be ongoing.

🎛️ Flexibility & Control

- Parallelism - multiple activities can be open for the same unit, progressing independently.

- Collaboration - several operators can work together on the same activity.

- Dynamic updates - new Flow versions can update or adapt activities already in place, while preserving full traceability.

- Real-time visibility - supervisors see overall progress, identify bottlenecks, and ensure sequencing constraints are respected.

Why it matters

This feature is crucial for industries where parallel execution plays a critical role:

- Real-world fit – no more workarounds with virtual splits or forced sequences.

- Faster assembly – reduce bottlenecks by allowing multiple operations at once.

- Better quality control – each activity carries its own checks and traceability.

- Workforce alignment – operators only see the tasks they are certified to perform.

- Performance insights – time tracking feeds accurate labor reporting into ERP.

Because this capability is embedded in the Industrial Equipment template of CM MES, it is purpose-built for sectors such as industrial machinery, energy, and aerospace — industries where large-scale discrete manufacturing requires maximum flexibility.

Final Thoughts

Complex manufacturing is rarely linear. Operators don’t wait in line for one task to finish before beginning the next — they work side by side, in parallel, to keep production moving. Traditional systems often force these realities into rigid, sequential workflows, slowing down operations and creating unnecessary workarounds.

Process Activities in CM MES change that. By giving each task its own rules, checks, and traceability — while still fitting seamlessly into the overall Flow—manufacturers gain the flexibility to mirror how assembly truly happens on the shop floor.

The outcome is not just speed and efficiency, but also clarity and control: supervisors see progress in real time, operators focus only on what they’re certified to do, and every activity remains fully traceable.

Author

Hello! My name is Diogo Cunha. ✌️

I’m a Functional Analyst at Critical Manufacturing, working in the Solution Delivery area. I’m passionate about bridging shopfloor operations with MES solutions.

Outside work, you’ll usually find me building with Legos or enjoying time in nature.

You can find me on LinkedIn.